Drone Frame Optimization

December 2023

Through dual-load-case FEA, topology optimization, and targeted parametric studies, I reduced the drone frame from 788 g to 216 g while meeting all stress, displacement, and symmetry requirements. The final spoke-based design, developed in SolidWorks and ParetoWorks, remains both lightweight and practical to manufacture.

Design Optimization

The Process

Design Envelope & Load Cases

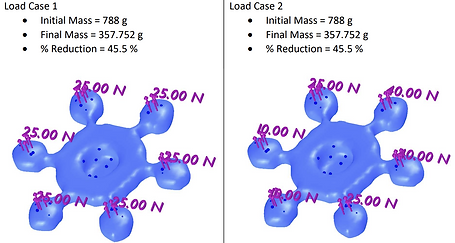

I began with FEA on the unmodified envelope to understand baseline behavior under the two required scenarios:

-

Hover Load – bottom face fixed, six 25 N loads applied at mounting pads.

-

Tilt Load – bottom face fixed, with asymmetric applied loads of 40/25/10 N across pad pairs.

Both analyses confirmed that the envelope’s stiffness and low stresses gave me a wide feasible space to remove mass safely.

Skills & Tools: Finite Element Analysis, SolidWorks

Topology Study

Using ParetoWorks, I ran a combined-load topology study to efficiently generate one solution that satisfied both scenarios.

Key constraints included:

-

≤35% final mass goal

-

Six-lobe symmetry

-

Preservation of nondesign regions

-

Max VM stress ≤3.2 MPa

-

Max displacement ≤5 mm

Across three identical studies, ParetoWorks consistently converged on a spoke-like design with tapered fins and thinning toward the outer rim. These features became the core architecture for my final part.

Skills & Tools: SolidWorks, ParetoWorks, Topology Studies

Parametric Optimization

Guided by the topology output, I built two levels of design studies to optimize mass through four key global variables.

Initial Study (~150 iterations):

Used coarse steps (~5 mm) to bracket feasible regions and understand how extreme values impacted stress and stiffness.

Refined Study (~80 iterations):

Used 1–2 mm step ranges around the optimal zone found in the first study.

Results showed:

-

A larger slot length and smaller inner radius reduced mass most effectively.

-

Fin thickness could safely decrease without compromising stiffness.

-

These insights established the geometric boundaries of the final frame.

Skills & Tools: Design Studies, Design Optimization

Design Validation

The final design achieved:

-

216.26 g total mass (27.4% of original)

-

3.183 MPa max VM stress (within target)

-

0.2069 mm max displacement (far below allowable)

Minor adjustments—like moving slots inward to avoid mounting-pad fillets and slightly thickening fins—ensured the final model met all nondesign constraints while keeping mass low.

Extra Consideration

Manufacturability Considerations

I evaluated both 3D printing and injection molding:

-

FDM 3D printing is practical for prototyping but would require support structures due to the underside taper, potentially affecting surface finish.

-

Injection molding better accommodates the underside geometry, though the through-slots complicate mold design.

-

The final geometry remains manufacturable with either method, depending on production scale!